Introduction

Shende Sales Corporation is India’s leading Industrial Rubber Bushes Manufacturer. Rubber Bush is a type of vibration isolator that provides a flexible interface between two rigid parts. The rubber on shock absorbers acts as a buffer, absorbing and damping energy produced by the interaction of these two parts.

Industrial rubber bushes may not be the most glamorous parts in the industrial industry, but they are essential to many different sectors, helping to ensure that machinery runs smoothly and effectively. These modest parts are in charge of lowering vibration, noise, and eliminating metal-to-metal contact, which increases overall safety and increases the lifespan of machinery. We’ll dig into the world of industrial rubber bushes in this essay, looking at their varieties, uses, and significance to business operations.

What Are Industrial Rubber Bushes?

Industrial rubber bushes are rubber or elastomeric-made parts that are frequently attached to metal sleeves or cores. They are also known as rubber bushings or rubber mounts. These parts are utilized in many mechanical systems to offer cushioning, vibration isolation, and noise reduction. They are intended to reduce noise, avoid metal-to-metal contact between moving components, and absorb and dampen vibrations, thus increasing the lifespan of machinery and equipment.

Types of Industrial Rubber Bushes

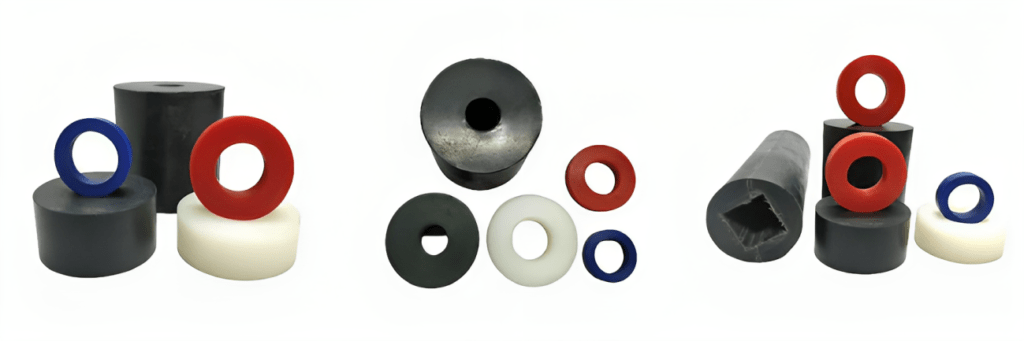

Cylindrical Rubber Bushes: These rubber bushes, which come in a variety of patterns, are the most popular kind. They are often utilized in engine mounts, suspension systems, and other automotive applications.

Conical Rubber Bushes: These curved bushings are often used in situations where it is necessary to preserve the alignment of two components while allowing for angular movement.

Spherical Rubber Bushes: Spherical rubber bushes are versatile and allow for movement in multiple directions, making them suitable for applications with complex motion requirements.

Barrel Rubber Bushes: These bushings feature a cylindrical body and a flange that serves as a mounting flange. They are frequently found in the suspension systems of automobiles.

Donut Rubber Bushes: Also known as doughnut or toroidal bushes, these have a toroidal shape and are used in a wide range of applications, including engine mounts and suspension systems.

Applications of Industrial Rubber Bushes

Automotive Industry: Vehicles often use rubber bushes to lessen noise and vibration from the road. They are frequently found in stabilizer bars, control arms, engine mounts, and suspension systems.

Industrial Machinery: Rubber bushes are used in a variety of equipment parts in the manufacturing and processing sectors to reduce vibration and noise, guaranteeing smooth and effective operation.

Aerospace Industry: Aircraft use rubber bushes for damping and reducing vibration in engine mounts, landing gear, and other critical components.

Agriculture: Rubber bushes are used in agricultural machinery to cushion shocks and vibrations, enhancing user comfort and extending equipment life.

Construction: Rubber bushes are used in the suspension systems of heavy construction machinery like bulldozers, cranes, and excavators to tackle difficult surfaces.

Rail Transportation: Rubber bushes are vital in rail transport, helping to reduce vibrations and noise in train carriages and locomotives.

The Importance of Proper Selection and Maintenance

To guarantee optimum performance and equipment longevity, it is essential to choose the proper kind and grade of rubber bushes. When choosing rubber bushes, one should take into account the needs of the application, load capacity, temperature range, and exposure to chemicals or environmental conditions. The safety and effectiveness of machinery might be jeopardized by worn or broken bushes, thus routine inspection and maintenance are also crucial.

Advancements in Rubber Bush Technology

Advancements in materials science and manufacturing technology have led to the development of high-performance rubber bushes. Some of the notable innovations include:

Improved Materials: Modern rubber compounds offer better resistance to heat, chemicals, and wear, ensuring longer service life.

Design Optimization: Computer-aided design (CAD) and finite element analysis (FEA) have allowed for the optimization of bushing shapes and structures to enhance performance.

Retrofit Solutions: Some manufacturers offer retrofit solutions that allow for the easy replacement of old rubber bushes with improved, longer-lasting alternatives.

Conclusion

Despite rarely receiving much attention, industrial rubber bushes are essential parts of many different businesses. The smooth and secure functioning of machinery and equipment is made possible by their capacity to absorb vibrations, minimize noise, and avoid metal-to-metal contact. Rubber bushes will become progressively more important as technology develops in terms of improving the effectiveness, security, and sustainability of industrial processes. These tiny parts make a significant influence in a variety of industries, including aerospace, manufacturing, and the automobile sector.