Circlips Manufacturer in India

Table of Contents

Introduction

Shende Sales Corporation established in the year of 1988. We are a Leading Industrial Rubber O Ring Manufacturer, Wholesaler, and Supplier of O Ring and Oil Seals that include Rubber Seals, Rubber Rings, Rubber Extruded / Moulded Products, Rubber Bellow, Rexene Bellow, Diaphragm, Rubber Gasket. These are available in various specifications that meet national and international quality standards.

The smallest parts frequently have the most important functions in the broad and complex field of mechanical engineering, where accuracy and dependability are critical. sometimes referred to as snap rings or holding rings, are one of these unsung heroes. In various applications, these seemingly straightforward metal rings are essential for anchoring parts within an assembly, preventing axial movement, and guaranteeing smooth operation.Knowing what makes a great circlip and why selecting the proper provider is crucial are important considerations if you’re searching for a top-tier Circlips Manufacturer in India. Businesses like Shende Sales Corporation, which provide not just goods but also solutions that propel business growth, really shine in this area. We are the best Circlips Supplier.

What Exactly Are Circlips

Consider a shaft that has a bearing or gear that must remain in a particular location while maintaining free rotation. A circlip is useful in this situation. Designed to be snapped into a machined groove on a shaft (external circlip) or inside a bore (internal circlip), this semi-flexible metal ring has open ends. Once positioned, it serves as a shoulder to keep the part from shifting from its designated position. It is impossible to exaggerate their significance. are found in everything from large machinery to the tiniest electronic devices. They are important in. We are the Best Circlips Manufacturer.

Why Choose Shende Sales Corporation

- Unmatched of Experience and Expertise: Having worked in the field for more than thirty years, we offer unmatched expertise and a thorough comprehension of producing precision parts. Because of our vast experience, we’ve seen it all, found solutions, and improved our procedures throughout time to provide the best. We are experts, not only manufacturers.

- Excellent Material Quality: We think that excellent raw materials are the foundation of any fantastic product. Only premium spring steel and other materials are purchased by Shende Sales Corporation from authorized certified producers. Every circlip we make is guaranteed to be long-lasting, dependable, and to operate at its best because to our fundamental dedication to quality.

- Strict Quality Control and Certifications: Our commitment to quality is ingrained in our operations and goes beyond a simple pledge. We employ a group of skilled engineers that carefully examine each batch as part of our strong quality control system. We adhere to important international and Indian quality standards, including European, and American. We ensure continual improvement by communicating our quality policy clearly and reviewing it on a regular basis.

- Internal Research and Development and Customization Skills: We are aware that each project is different. Whether you have a specific size, material, or design requirement, our knowledgeable R&D department and talented team can collaborate closely with you to design and produce custom circlips that precisely match your specifications. Optimal performance and smooth integration into your assembly are made possible by this versatility.

- Contemporary Manufacturing Plant: We use cutting-edge machinery and technologies in our production procedures to guarantee accuracy, effectiveness, and constant quality. We are able to maintain the highest standards while maintaining globally competitive prices thanks to this technological investment.

- Customer-Centric Approach: The foundation of Shende Sales Corporation’s success is client happiness. We are renowned for being straightforward, approachable, and open in our interactions. From machine operators to sales coordinators, our highly qualified staff is committed to delivering an exceptional client experience from the initial inquiry to the on-time delivery.

- Dependable Supply Chain and On-Time Delivery: We take great satisfaction in our just-in-time delivery and quick order turnaround times. We guarantee that your arrive at your door when you need them thanks to our dependable logistics partners, reducing downtime and maintaining uninterrupted business operations.

- A Wide Range of Industrial Solutions: Although we specialize in our knowledge of industrial rubber goods allows you to get several parts from a single, reliable supplier, which streamlines the procurement process.

Applications of Circlips

- One of the biggest markets for circlips is probably the automotive sector. They play an essential role in braking systems, steering mechanisms, transmissions (holding gears, bearings, and shafts), engines (securing piston wrist pins or gudgeon pins), and many other parts. In automotive applications, circlip dependability is crucial for ensuring both performance and safety.

- Industrial Machinery: Circlips are utilized to secure rotating shafts, bearings, gears, pulleys, and linkages in everything from precision manufacturing tools to heavy-duty construction equipment. By avoiding axial play and wear, they help innumerable machines run smoothly and effectively.

- Electronics and Appliances: Circlips secure Printed Circuit Boards connectors, switches, and other fragile parts in place in smaller, more complex devices. They are necessary to guarantee the longevity and correct operation of industrial electronic equipment, home appliances, and consumer electronics.

- aircraft Industry: Circlips are used to fasten hydraulic cylinders, actuators, landing gear components, and other essential elements in aircraft applications where accuracy and dependability are crucial. They are perfect for tough aircraft conditions because of their robustness and lightweight design.

- Pumps and Motors: Circlips are frequently used in a variety of electric motors and pumps to hold onto impellers, bearings, and other rotating parts, guaranteeing effective power transfer and avoiding component displacement.

- Textile Machinery: To ensure the smooth and accurate operation of the machinery, circlips are frequently used to secure various shafts, rollers, and gears in the intricate movements found in textile machines.

- Agricultural Equipment: To endure harsh environments and preserve operational integrity, circlips are used in the powertrains, hydraulic systems, and other assemblies of tractors, harvesters, and other agricultural gear.

- Switchgear: To guarantee appropriate electrical contact and mechanical stability, circlips are employed to hold interior components in electrical switchgear.

Specifications Table of Circlips

| Type | Shaft/Bore Diameter (mm) | Material | Finish | Thickness (mm) | Standards |

|---|---|---|---|---|---|

| External Circlip | 3 – 300 | Spring Steel / SS304 | Black Oxide / Phosphate | 0.3 – 3.0 | IS 3075 / DIN 471 |

| Internal Circlip | 3 – 300 | Spring Steel / SS316 | Zinc Plated / Plain | 0.3 – 3.0 | IS 3075 / DIN 472 |

| E-Clips | 1 – 50 | Phosphor Bronze / Steel | Natural / Coated | 0.2 – 2.0 | DIN 6799 |

| Spiral Rings | Custom sizes | Stainless Steel / Carbon Steel | Oil Finish | As per design | DIN 983 / 984 |

Benefits of Circlips

- Their main purpose is to ensure secure retention. In order to stop parts from moving axially along a shaft or inside a bore, circlips efficiently form a “shoulder” inside a groove. The integrity of the assembly and operational effectiveness depend on this tight fit.

- Cost-Effective: Circlips are a very affordable alternative to many other attaching techniques, such as threaded fasteners or intricately machined shoulders. Their price is a result of their straightforward design and effective production techniques.

- area-Saving Design: Circlips require little radial area to install because they are naturally low-profile. They are therefore perfect for uses where little designs are necessary.

- Simple Installation and Removal: Circlips are simple to install and remove with the correct equipment, usually circlip pliers. As a result, maintenance and repair activities are made simpler and assembly lines are streamlined.

- High Strength and Durability: Made from premium stainless steel or spring steel, circlips are made to endure frequent use, high stress, and vibrations without compromising their structural integrity. They can function dependably in demanding conditions, such as those with temperature fluctuations and corrosive substances, and they are fatigue-resistant.

- Versatility: Circlips are available in a wide range of shapes, sizes, and materials to accommodate a variety of uses. There is a circlip made for practically every purpose, whether it is an external circlip that secures parts to a shaft or an internal circlip that fits into a bore. E-clips, C-clips, and other lugged or non-lugged designs are common varieties.

- Preventing Lateral Movement: By offering a rigid hold, circlips guarantee that parts stay in their exact positions and stop any unwelcome side-to-side movement that might cause wear, misalignment, or failure.

Types of Circlips

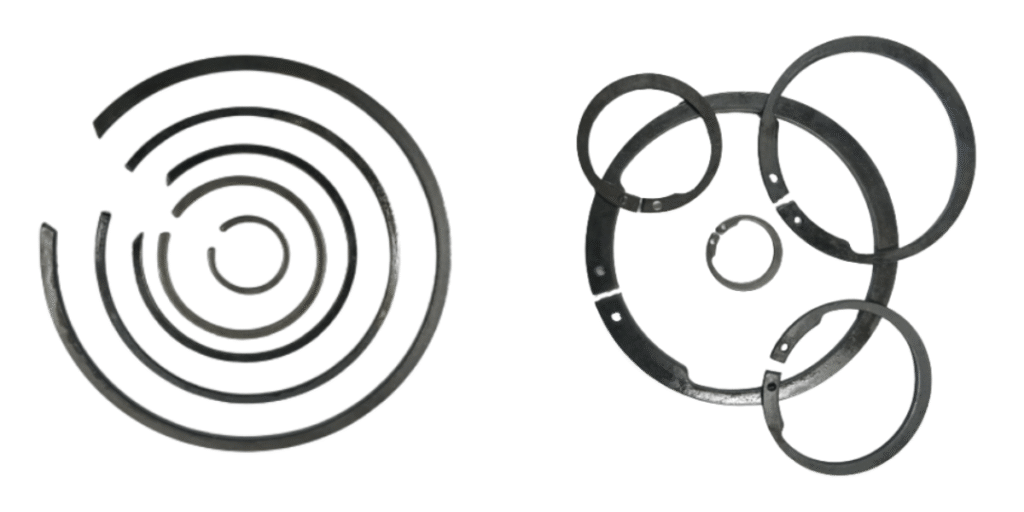

1. External Circlips

- Fit around the outside of a shaft.

- Prevent axial movement of components.

- Commonly used in automotive and mechanical systems.

- Material: Carbon steel, stainless steel.

- Size Range: From 3 mm to 200 mm diameters.

2. Internal Circlips

- Fit into a groove inside a bore or housing.

- Hold components such as bearings or sleeves in place.

- Widely used in gearboxes and motors.

3. E-Type Circlips

- Shaped like the letter “E”.

- Fit onto shafts and provide radial grip.

- Easy to install and remove.

- Used in electronics, toys, and small engines.

4. Snap Rings (Axial and Radial)

- Axially or radially mounted retaining rings.

- Can be either external or internal.

- Common in transmission systems.

5. Spiral Retaining Rings

- Flat wire rings without protruding ears.

- Ideal for high RPM applications.

- Available in single-turn and multi-turn designs.

6. Heavy Duty Circlips

- Thicker, more durable version for high-load applications.

- Used in heavy machinery and construction equipment.

Conclusion

Circlips, though small in size, are indispensable components that underpin the reliability and functionality of countless machines and devices around us. Their ability to securely hold parts in place while allowing for essential movement makes them true workhorses in modern engineering.

India’s manufacturing industry has advanced significantly in creating high-quality circlips, presenting a strong argument to buyers worldwide looking for reliable and affordable options. Shende Sales Corporation is a testament to the manufacturing prowess of India within this dynamic landscape. We are your perfect partner for all of your circlip needs because of our decades of experience, dedication to using high-quality materials, precision engineering, and a focus on customer satisfaction. Count on Shende Sales Corporation to supply the minor parts that have a significant impact on the functionality and durability of your goods.